Features

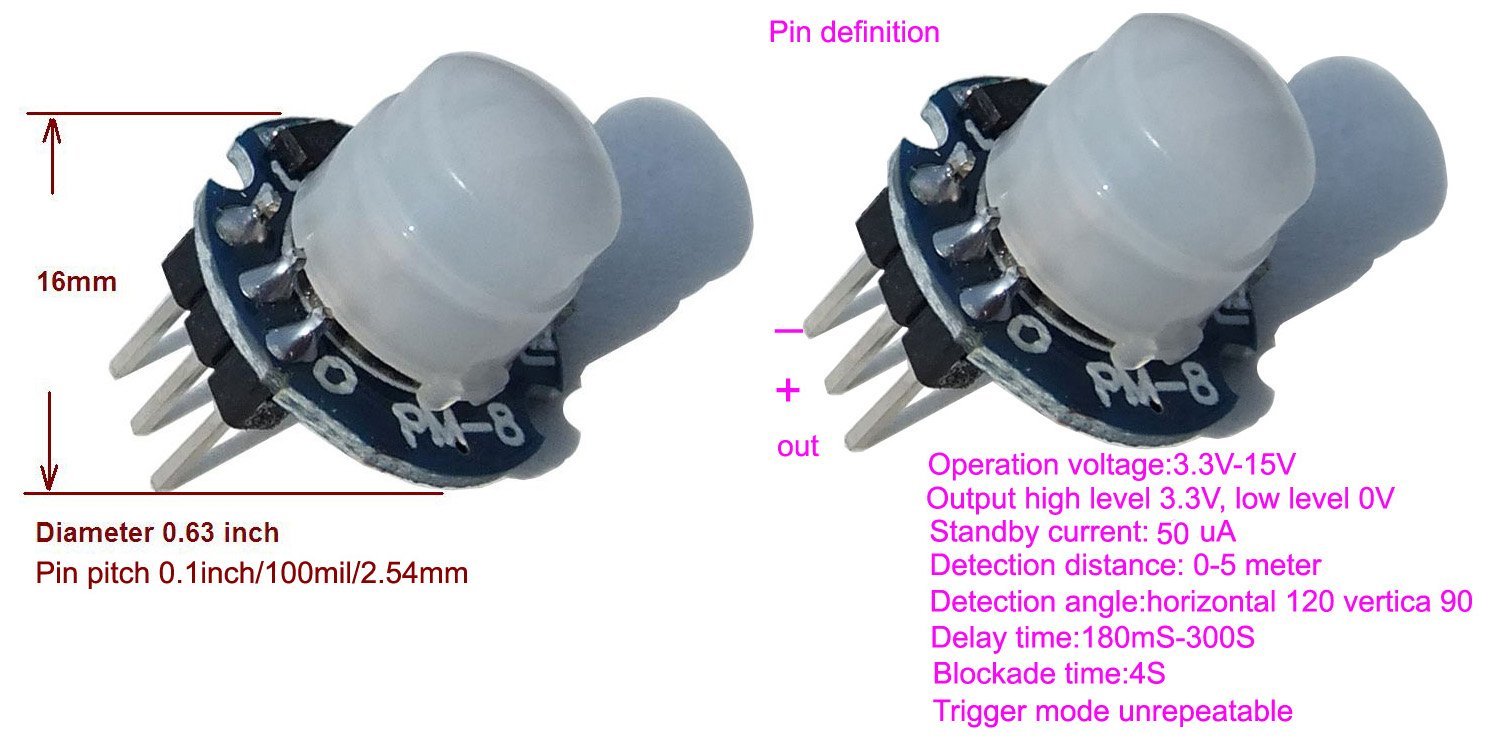

Power supply is 3.3V to 15V.module include LDO;

Sensitivity can be adjust,

Delay time can be adjust,

Trigger mode is be defined as repeatable;

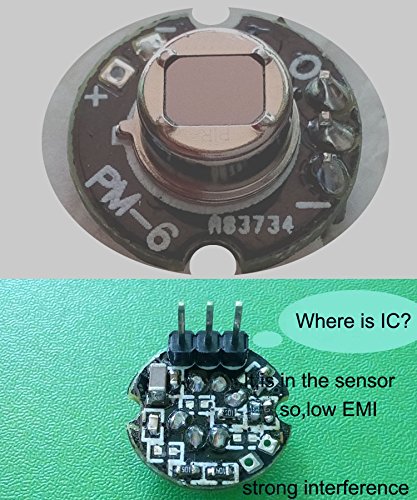

[small size,Wideer working voltage range,small current,stable performance]

Repeatable: if the moudul detect human body is moving,output high level at once,this moment,at delay time,if PIR detect body is moving once more, then delay time reset,be cleared to zero,start counting from zero,until the delay time to over,will output low level,waitting next trigger.

Unrepeatle:if the moudul detect human body is moving,output high level at once,this moment,signal input line be closed,PIR detect is disabled, until the delay time to over,will output low level,waitting next trigger.

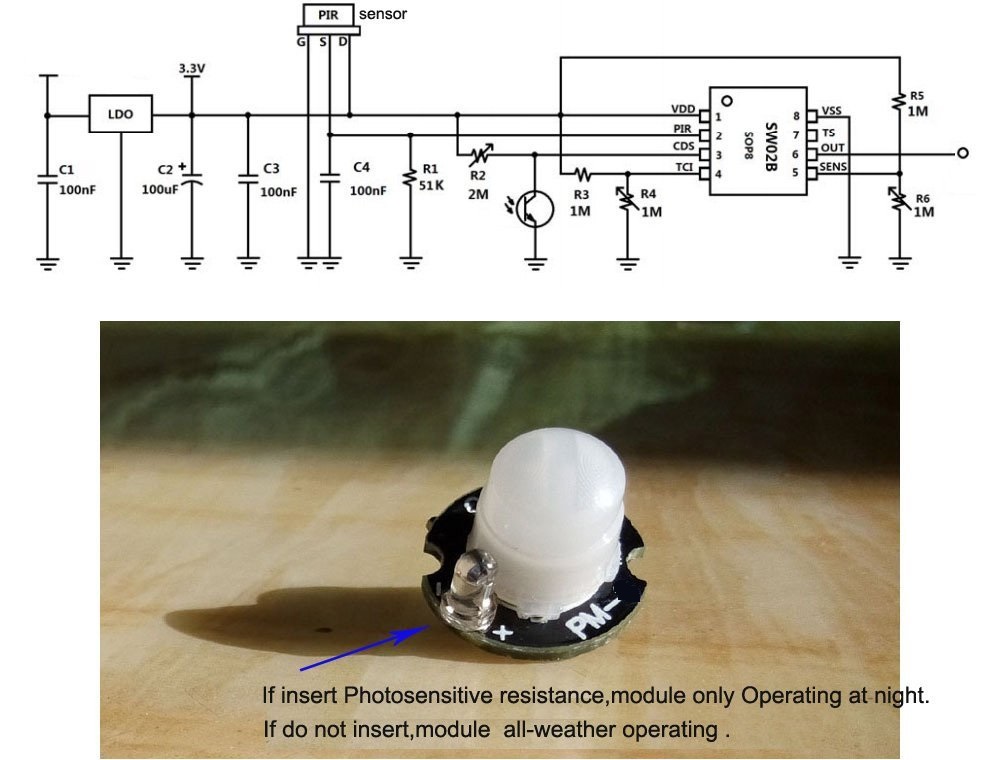

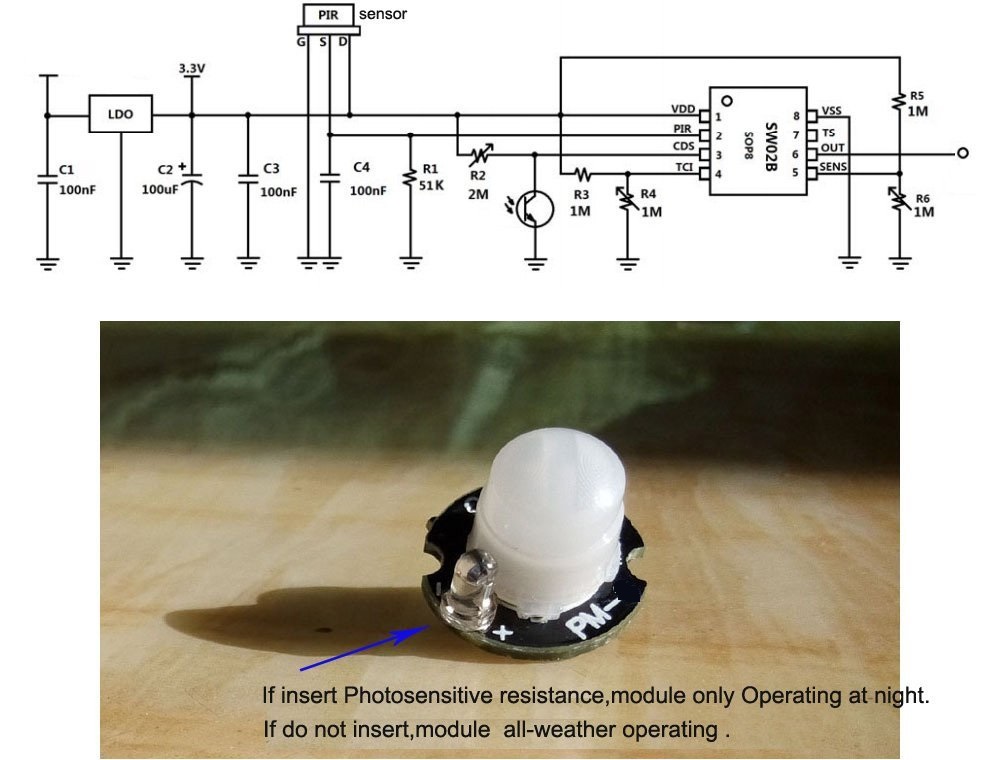

LDR worke mode

Customer can sold a LDR then the module will not work at the day time and will work at the evening.

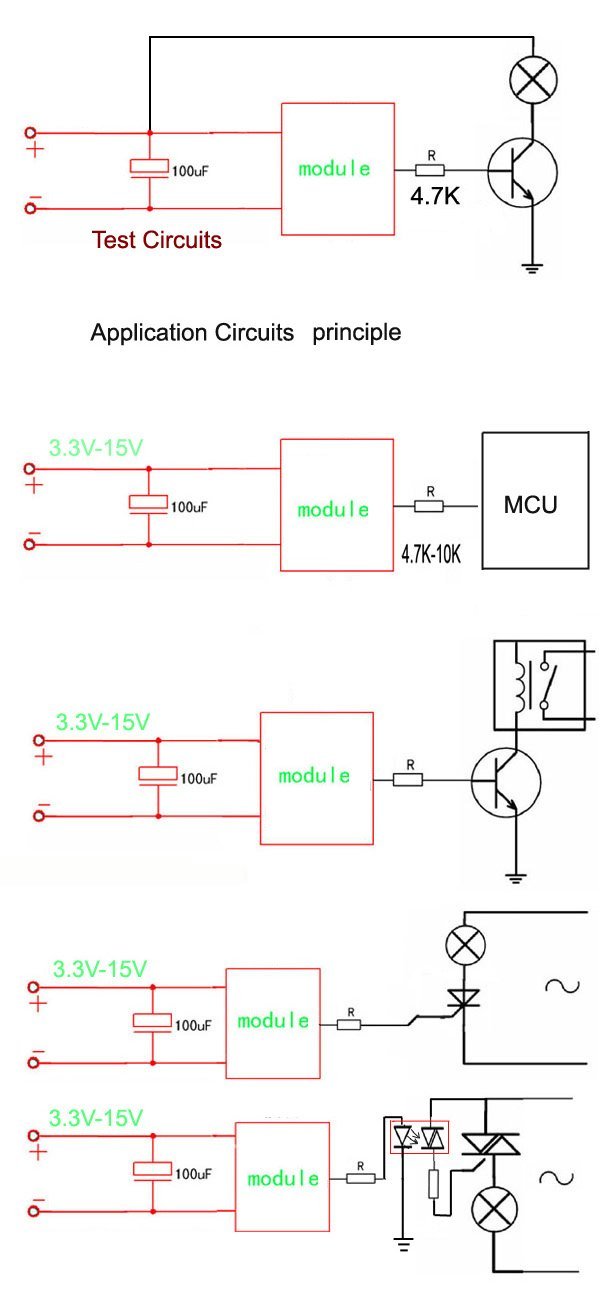

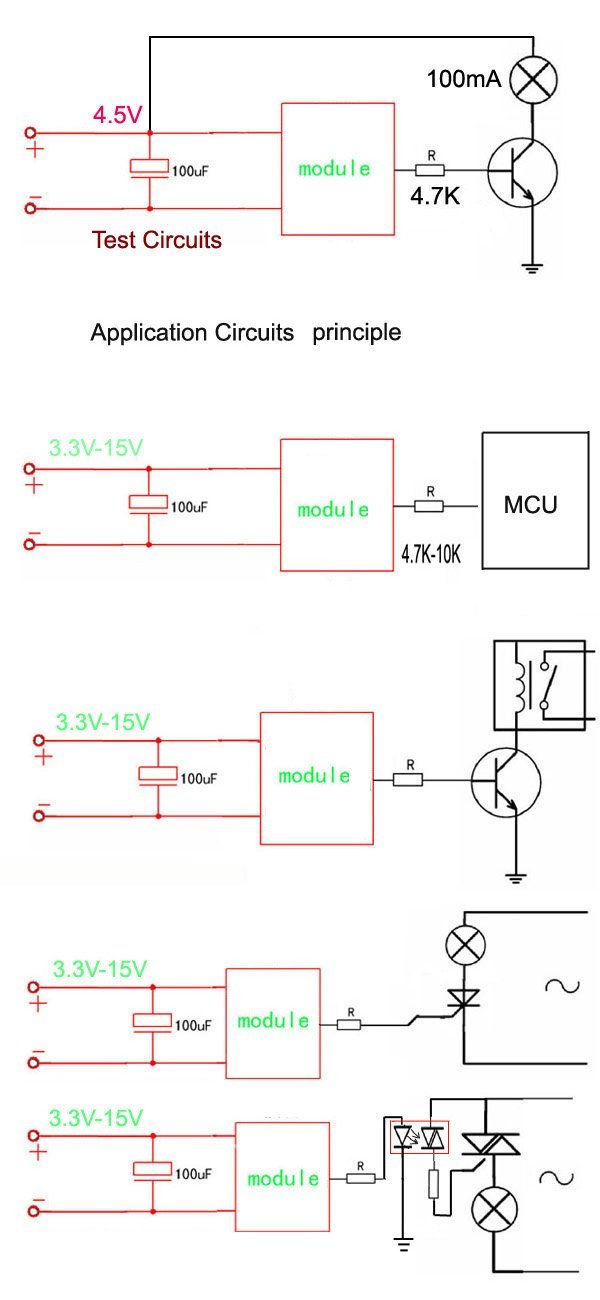

dwmzone-DWM-PM-2-Mini-Infrared-PIR-module-application-typical-diagram

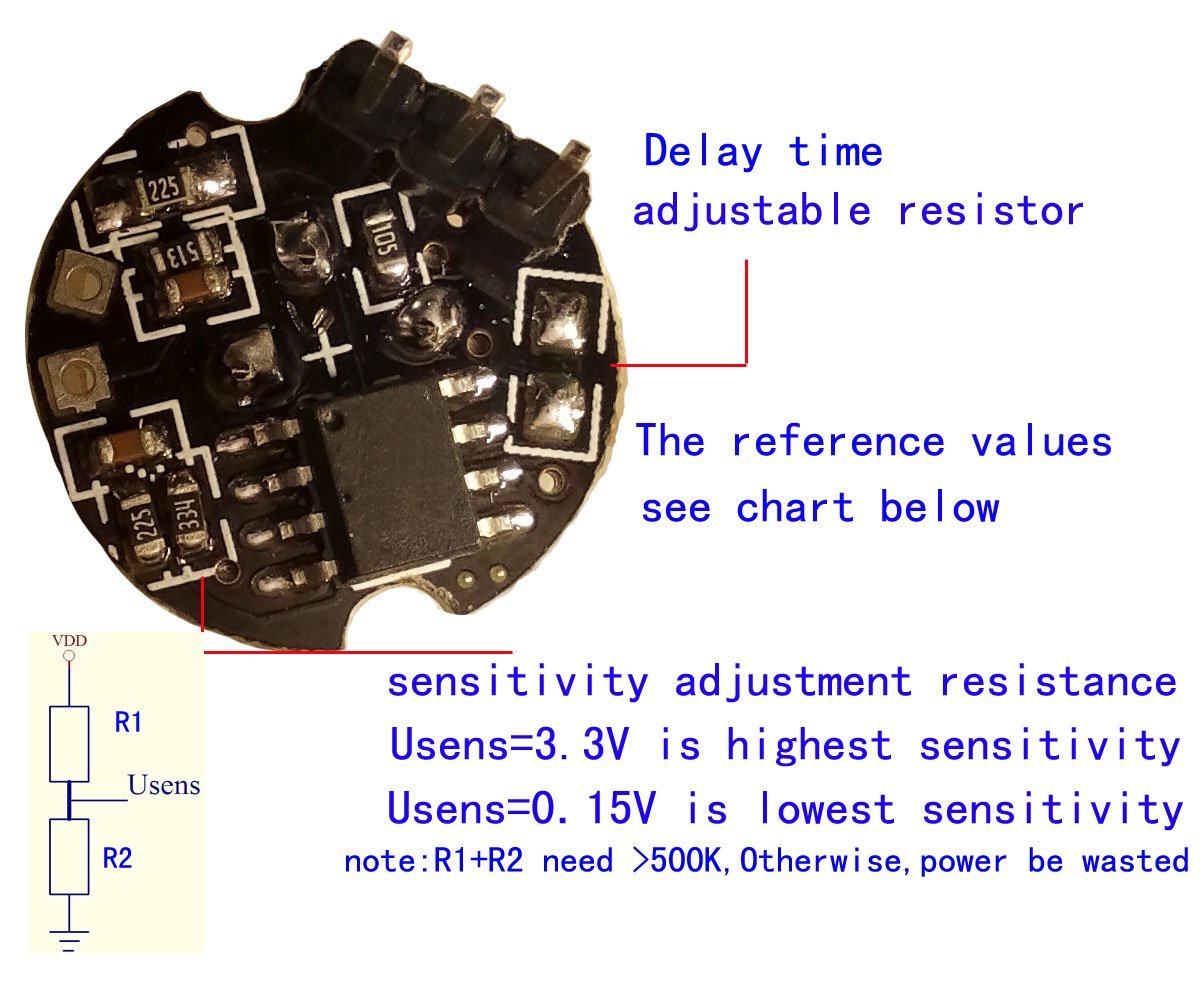

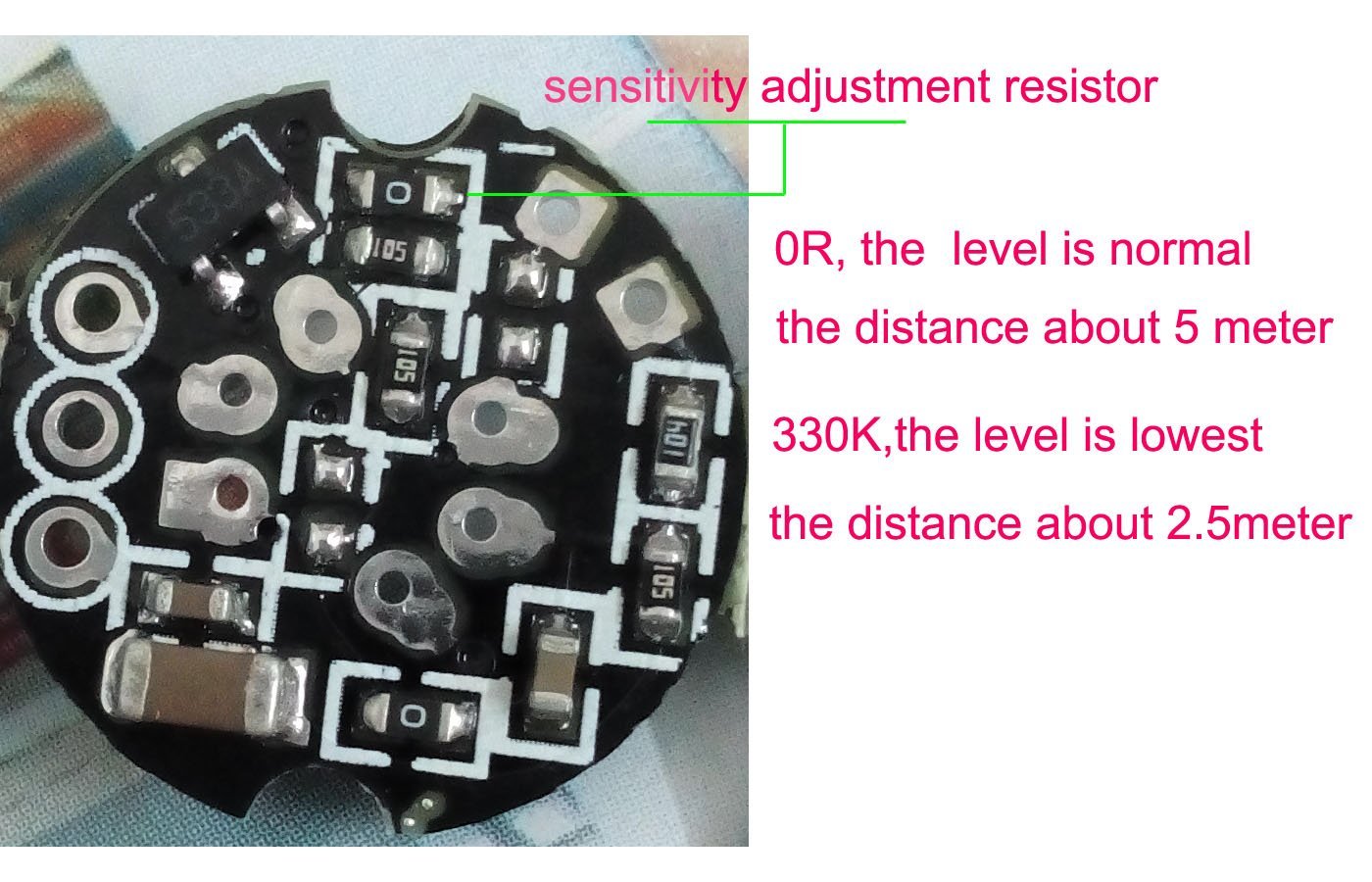

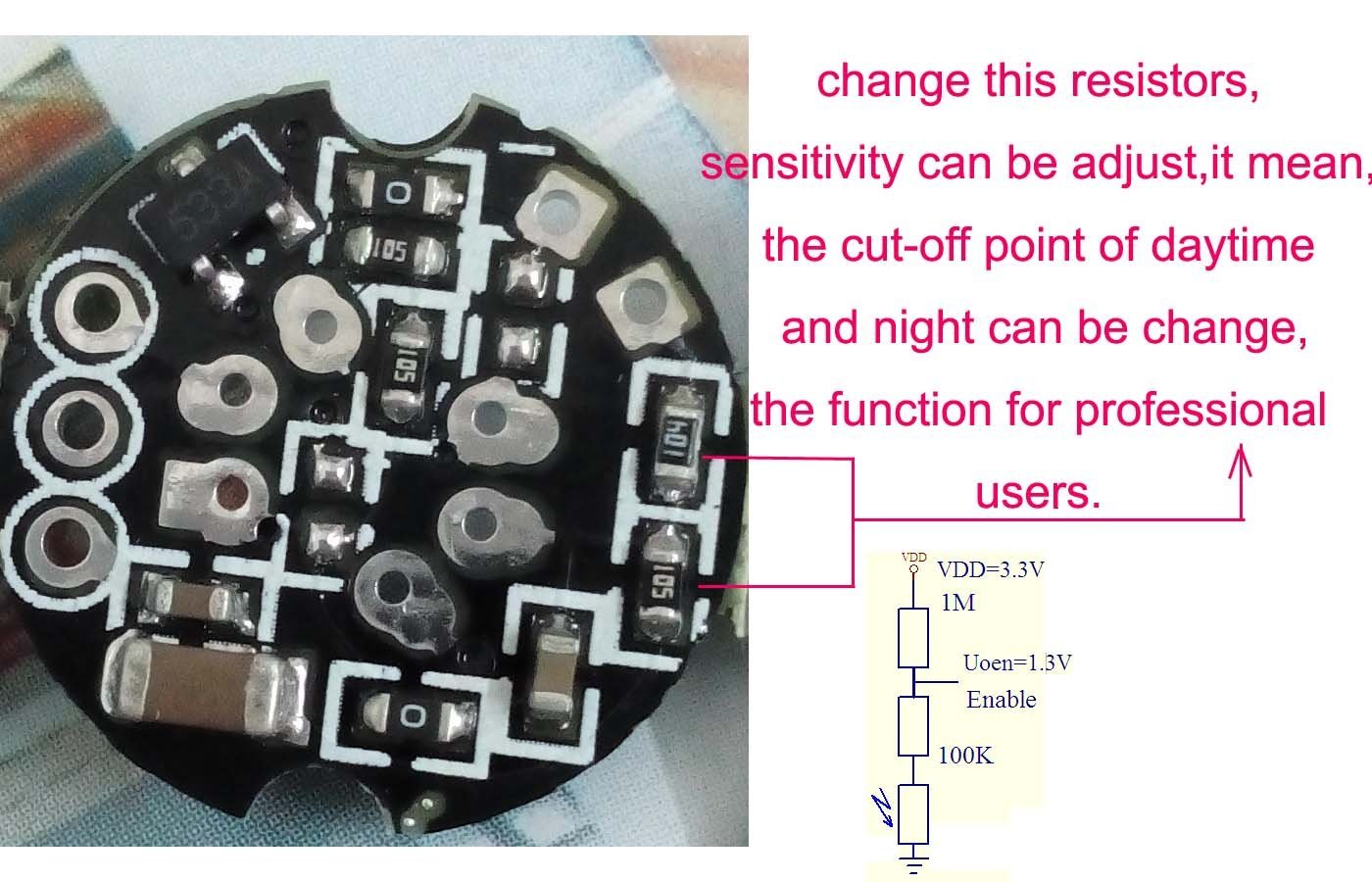

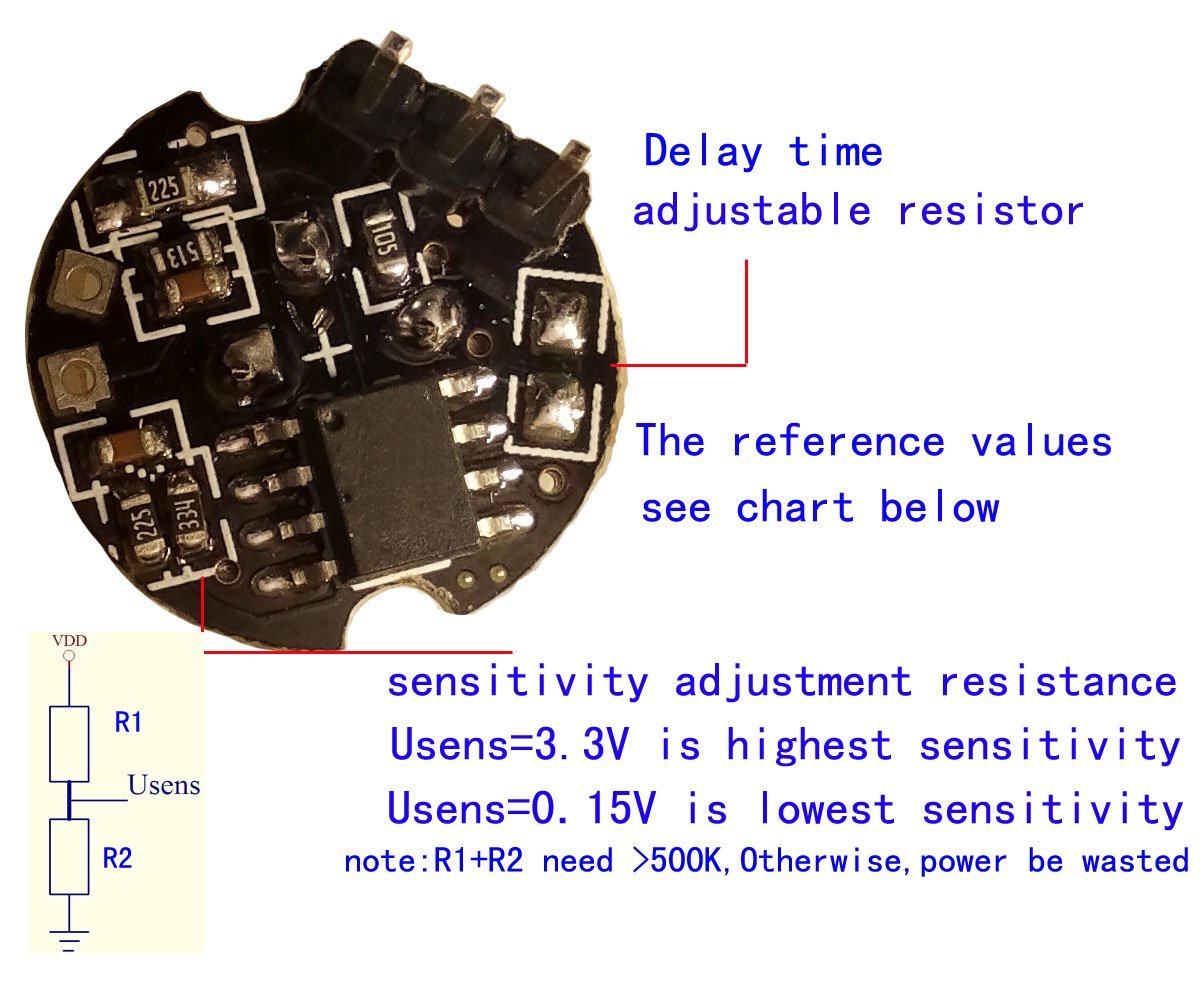

Sensitivity adjust and Delay time adjust

delay time adjust and sentivity adjust

If you want to change the sensitivity level you can folow the formula Usens=R1/(R1+R2)*VDD.if the Usens=3.3V it’s highest sensitivit and if the Usens=0.15V is Lowest sensitivity.You also have to consider the power comsumption For Lower Power comsumption the Resistance value of R1+R2 should Over 500k ohm.

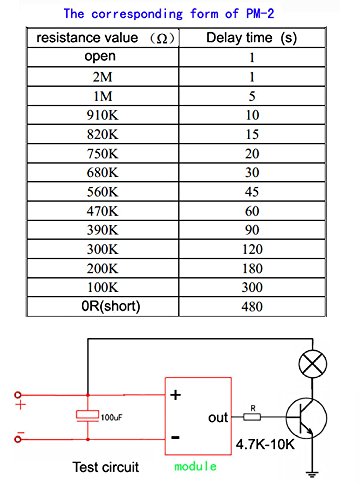

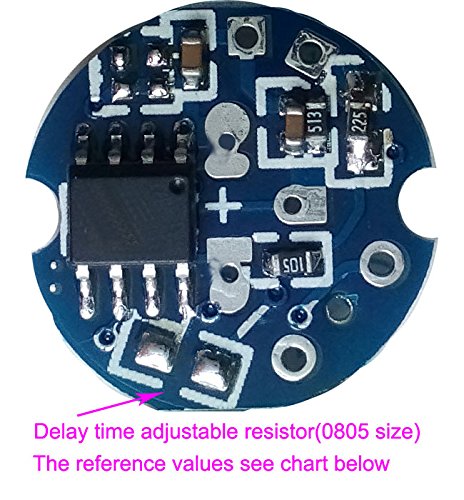

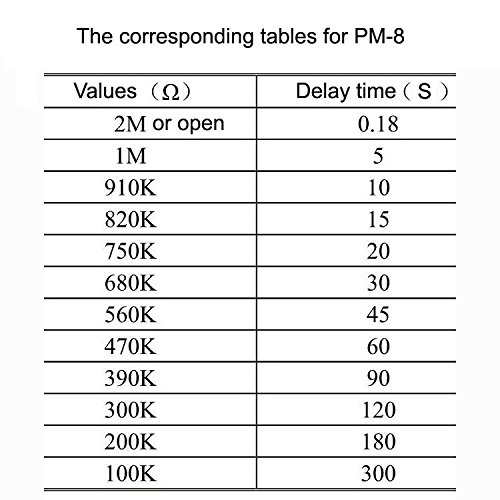

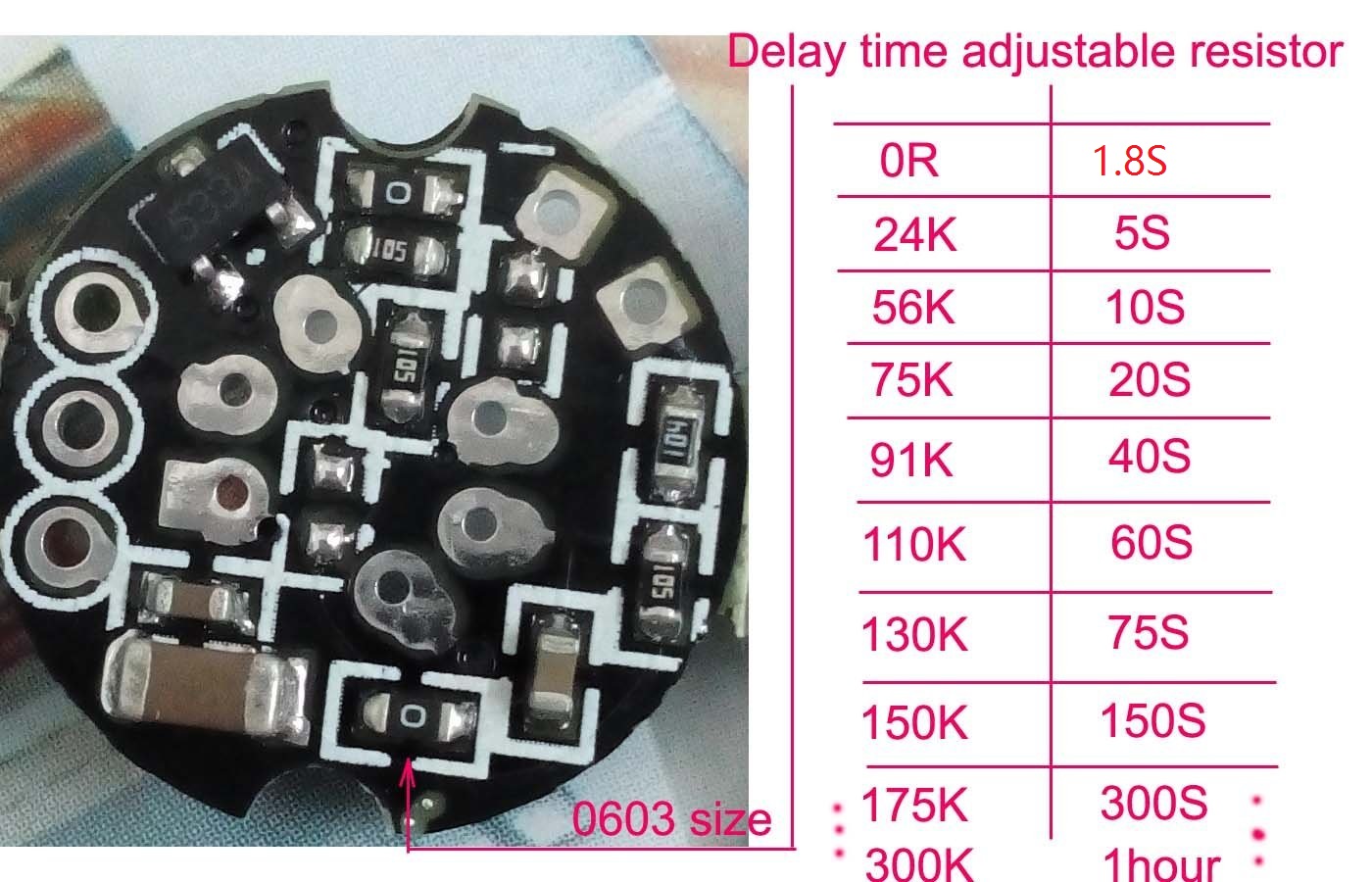

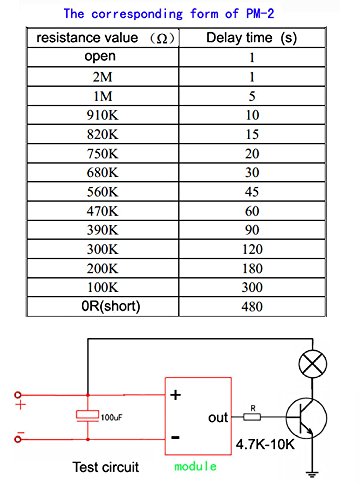

if you want to change delay time take this tale as reference shows as below.

delay time adjust reference table

The module ouput is MCU IO port direct output,to use,advise series connection a resistance,4.7K to 10K;

Note:

1.Before use,need checking Solder iron temperature , implement leakage of electricity, and static discharge in winter(cmos component)

2.When power on,IC has 20S to 60S self-testing process,in the meantime,will output high level,then,output low level,into stable waiting state.(waiting state,it is also on standby);